If the Frank Bacon Machinery Company ever decides it needs a corporate motto, one likely candidate might be: “What’s Next?” For the past 70 years, Frank Bacon Machinery has been in business in and around Detroit. Its focus has shifted through the years, from stamping and grinding units to today’s sophisticated tensile and compression devices. But none of it would have happened had Frank Bacon not retired from the Marines at the end of World War II, moved back home to Michigan, and wondered, “what’s next?” Today, John Stencel IV, is president of the mechanical testing business his grandfather Frank founded in a one-room office on Detroit’s 8 Mile Road in 1953. He describes Frank Bacon as a voracious reader who foresaw Detroit’s emergence as the hub of America’s postwar auto industry, and who taught himself the basics of the machinery business he knew would be an integral part of that development. “He figured Detroit would become a haven for machinery manufacturing,” Stencel says. “So he read all he could and taught himself the business from the ground up. After he started his business he became one of the earliest members of the MDNA.” Much of America’s used machinery sales business is strengthened by deep family ties. Third-, fourth-, even fifth-generation operations are not uncommon. And each generation faces its own set of opportunities and challenges. “A lot of people who get into this business are a family member or know a family member,” Stencel says. He recalls his transition from Saginaw Valley State University to the working world in the spring of 2010 this way: “I graduated from college on a Friday and started that next Monday.” He went to work for his father, but gets his grounding in the machinery business from both the Bacon and Stencel sides of the family. And the MDNA is nothing anyone had to explain to him. “I’ve been around MDNA people since I was in diapers,” he declares. His father is a past President of the MDNA, and John IV started as a secretary of the Detroit/Toledo chapter and quickly moved up to be a representative on the national board. He currently holds positions as a national board director-at-large and chair of the MDNA’s public relations committee. Frank Bacon Machinery is in a third-generation location as well — all at different addresses along the 8 Mile Road corridor. It opened a 30,000-square-foot remanufacturing and storage facility four years ago, and still maintains a 10,000-square-foot testing lab and storage location as well as a 50,000-square-foot warehouse in Detroit. Two years ago, the company introduced its own line of new tensile and compression equipment — the Frank Bacon Machinery line. In addition to the new, used and remanufactured equipment, the company also offers engineering services, calibration, testing and training to its customers. And what’s next? Rest assured, at Frank Bacon Machinery, somebody’s already asking that question.

0 Comments

If you want to know how the machinery sales business in and around New York City has changed over the past half-century, David Valitt can tell you. “You either evolve or die,” is the way Valitt describes the approach that took his business from its roots in the bustling machine district streets of Manhattan’s lower east side to stops on Long Island and, finally, across the Hudson River to New Jersey. As Machinery Values, Inc., has evolved — and prospered — Valitt credits the Machinery Dealers National Association (MDNA) with having played an important role in the process. “The camaraderie is important,” he explains. “By being in the MDNA you’re finding new partners. You get together with other members, discuss your business trials and tribulations with them, and discover. in the end, that you’ve made some very close friends.” He says many of the dozens of used machinery concerns that left New York City for greener nearby pastures recognized that membership in the trade organization brings with it the assurance of personal and professional integrity, ethical practices, and practical knowledge. “They competed and worked with each other in New York and now they’re at the core of the MDNA today,” he says. Valitt became part of the MDNA in the early 1990s, after he graduated from the State University of New York at Oneonta and joined the business then owned by his father, Gene Valitt. It wasn’t long before he stepped up to the leadership ranks in the MDNA’s New York/New Jersey Chapter. He now serves as its vice chairman and as a member of the MDNA’s national board of directors. Valitt can recall the days when machinery was offered for sale through print catalogs. But Machinery Values, established in 1971, was not left behind when technology brought improvements and efficiencies to not only the equipment, but to the way it it is sold. “The Internet leveled the playing field,” he says. “Using Ebay, YouTube, LinkedIn, Instagram, and websites, the larger and smaller dealers now have the same sales reach.” Machinery Values offers its customers standard and CNC machinery of all sorts, including tooling, grinding, milling, routing, and lathe units and an array of cutting devices. More than 1,000 pieces of new and used equipment are displayed in the company’s 150,000-square-foot warehouse facility in Harrison, N.J., just nine miles from the Big Apple. Valitt was determined to put all the company’s equipment sales and service under one roof, and says what he has learned from friends in the MDNA helped make that happen. “We just evolved in the business,” he says. “We went along with the times.”  Welcome to “The Women of MDNA,” a series of posts where you’ll meet some of the remarkable women in our industry. Their contributions to machine sales in general, and our association in particular, enhance our organization and our industry on a daily basis. That’s especially true for Kristen Reeves, a relative newcomer to machinery sales, who’s making big strides as a sales representative at Automatics & Machinery in Longmont, Colorado. How did you get involved in the industry? I’m huge Denver Broncos fan. I came out to Colorado to visit my brother and cousin. When I told them that I want to live here, they told me that I need to get into machinery sales industry. I told them that I didn’t know anything about the industry. “We’ll teach you,” was their reply. That conversation led to an interview with Steve Beck, President of Automatics & Machinery. He’s been a member of MDNA since 1990 and was willing to teach me about the industry. I think he saw that I wasn’t afraid of learning technical details. I have come to specialize in high precision turning and multi-axis CNC Swiss. I learn new things every day about the details of what I’m selling—not only from doing a little homework but also learning from end users and other dealers in this industry. How has your company benefitted from MDNA? It’s great meeting people in the same industry and learning about their experiences. I know that if you’re in MDNA, we already have a connection. There’s a huge trust factor there. We’re all part of the same group and follow the same code of ethics. Most recently, I went to the Weekend with the Pros event. It was a great opportunity to get to tour local companies and see their warehouses and operations. What is the value women bring to the industry? I think women bring a comfort level to the process. My customers appreciate that I’m there to build a relationship with them. It’s my philosophy that if they trust me, they’ll come back. So I’m really focused on the future as much as the current sale. Once I establish a relationship, it’s long-term, and I pride myself on repeat customers. What advice would you give other women in the machinery sales business? I think it’s important to focus on customer service throughout the entire process and handle any issues along the way. That can include getting shipping quotes and preparing the machine for shipping. When customers see the completed process, they’re usually happy with the result. You have to build the trust factor. Mean what you say and say what you do. What do you like best about the industry? I really enjoy establishing a relationship with the customer. It allows me to build their trust and find out their specific machinery needs. In general, it’s a male-dominated field, so when I speak to customers on the phone, it seems like they really listen, and that helps me build rapport. I really take the time to educate myself when it comes to the specific models. When a woman understands what they’re saying on a technical level and can go into detail, they are sometimes surprised and think it’s impressive. I also enjoy teaching and training newcomers to the machinery world. Most recently I have been working with Steve’s daughter, Alyssa Beck. I see a lot of families in this industry, so it is not uncommon to find new generations joining the industry. Alyssa has been a great addition to our team!  Though they deal in big machines, industrial equipment dealers inhabit a small world. Nelson Martins says that’s what makes the Machinery Dealers National Association (MDNA) such an important part of his company’s future. Martins is owner and president of DiPaolo Machine Tools Ltd., based in the Toronto suburb of Mississauga, and among the largest machinery dealers in Canada. He’s also the vice chair of the MNDA’s Canada Chapter, and the chapter’s representative on MDNA’s board of directors. His long association with the MDNA has left him with a keen appreciation for how the organization binds would-be rivals as associates in a business that values and rewards trust. “It’s essentially a bunch of competitors,” he says of the chapter members. “But among them, there is trust at all levels. We view each other as colleagues. The more we talk about the things that interest us in the business, the more we become valuable resources for each other.” Like so many MDNA member businesses, DiPaolo Machine Tools is a family affair. Martins’ father-in-law founded it more than 50 years ago as a machine shop. Martins and his wife bought the shop and expanded into a used-machinery concern, then added new equipment lines in 2010. It specializes in retrofitting, rebuilding, and reassembling lathes, milling machines, grinders, and other heavy-equipment offerings. DiPaolo also holds a Canadian government certification that allows it to serve defense and security customers in both Canada and the United States. Most of its business is done in North America. DiPaolo joined the MDNA in 2006 and Martins says the benefits were apparent immediately. Martins joined the Canadian Chapter Leadership committee shortly thereafter. “I realized that many of my MDNA colleagues were volunteering their time for our collective benefit,” he says. “I decided ‘OK, now it’s my time to pay it forward.’ And I’m glad I have. It has been a very good experience, and we’ve closed some nice business as a result.” He likes working within the MDNA member ranks because the organization’s standards promote confidence. “First and foremost, this is absolutely a personal business,” he says. “As you work with people, they become ‘my guy’ for this service or that advice. And why is he ‘your guy’? Because you can trust what he says and does. You know you’ll get an honest assessment, and you’ll get a fair price. “And people give their business to those they trust.”  Tim Cromwell grew up around machinery. Now, the machinery has grown up around him. Once fascinated by the wood-turning equipment and small engines his father worked with, Cromwell found his career calling with the massive, complex industrial pieces he appraises and sells today. The knowledge he has accumulated through the years is what he likes to share with fellow dealers in his capacity as chair of the Philadelphia Chapter of the Machinery Dealers National Association (MDNA). Cromwell has been an MDNA member for more than two decades. His initial connections were made while he was a sales executive for machinery dealerships in the United Kingdom and the U.S., and continue now that he runs his own company — Ironside Machinery, headquartered in Riegelsville, Pa. Since 2015, he has been served in various MDNA leadership posts — as the organization’s public relations chairman, and currently as the Philadelphia area’s chapter leader and representative on the national board. He also spends time advising leaders of other MDNA chapters on how to make the most of their responsibilities. “Involvement is crucial,” he says of his commitment to the organization. “What good is membership in anything if you’re not going to take full advantage of what it offers you? Business is all about the relationships you build, and the MDNA is how you can build them.” Cromwell started out as an auctioneer so, not surprisingly, Ironside — the name connotes his fondness for the "big iron” of the industrial plant floor — specializes in appraisals and sales of used equipment. While much of its business is conducted around his home base in the Lehigh Valley near Allentown, Pa., Ironside’s customers have come from across North and South America, as well as Europe. The company also offers a clean-out service that empties facilities of everything, from the presses and milling machines down to the office chairs, to make the building ready for a new occupant. “Ironside Machinery would not be here without the MDNA,” he declares. “In the 2 1/2 years I have owned this business, 95 percent of the deals I’ve done have been with MDNA members.” The MDNA was established in 1941 and today has nearly 400 member companies worldwide. They include machinery dealers, auctioneers, and appraisers. A subsidiary group, the Association of Machinery & Equipment Appraisers (AMEA), is the world’s premier industrial appraisal association. Cromwell also is a member of AMEA. "My experience with the MDNA is something that has made me money and kept me in business,” he concluded. “Simple as that.” Welcome to “The Women of MDNA,” a series of posts where you’ll meet some of the remarkable women in our industry. Through MDNA, some have discovered a pathway to learn and grow, applying their skills and experience in a new way. Consider Michelle Guzzino, president of Exact Machine Service, who has already jumped into chapter leadership and is a shining example of what women can accomplish in the industry.

How did you get involved in the industry? In June of 2021, my husband and I bought Exact Machine Service. I manage the day-to-day operations for the business, including the sales department. I had no experience in machine sales, although I did bring a bit of experience in the manufacturing field, having worked in corporate finance for manufacturing companies in several different roles. We sell new and used equipment and provide services to many different machine brands and models, and we are always looking for new opportunities to add value to the manufacturing customers we support. What inspired you to enter this field? I had worked in corporate finance for 20 years. It got to the point where I wanted to learn something new and different and see how I could grow. My next step would have been to be a CFO, but I was leaning more toward the business side. That’s what led me to go in this direction. My experience in the manufacturing field my entire life made this opportunity appealing. Even though we’re in sales and service, I’m still connected to the manufacturing world. How else have you been involved in MDNA? Right now, I’m the secretary for the Philadelphia chapter. Getting involved in leadership in MDNA has been so helpful. I get to hear more and understand more about the field. Right now, I’m still learning and growing, but depending on positions that might open up for me in the future, I would be willing to look into different leadership roles. What is the benefit of being involved in MDNA? One of the biggest benefits on being involved in MDNA is the relationships you build with other people in the industry. Our chapter encourages the members to connect and build relationships. Most of the time, they’re your competitor, but they’re still willing to help. I came in with no experience. The guys I met were willing to share their experience and best practices in this market and brainstorm ideas. The other way MDNA brings value is the business opportunities it affords. Someone else may have the right customer for a machine you’re trying to sell, so you can partner with other members to make a deal. Once you partner with them, they might come to you with opportunities. There’s a lot of respect in this industry, and people are ethical as they do business. If they know that you are working on that opportunity, they won’t come after it. They are more concerned about how we can we help each other out, and I really appreciate that. What is it like working as a woman in a male-dominated industry? In my opinion, men and women are capable of the same things. If you like a subject, you’re going to study and be just as qualified as anyone else. I’m not treated differently. If I treat people with respect, if I listen to them and understand where they’re coming from, most people appreciate that. It's so important to be honest and humble. I think it’s helpful to ask questions, such as, “Can you explain that a little bit better?” Or “I was thinking about this. What do you think?” People are more receptive to that kind of approach. What do you like best about the industry? This is an industry that is open to everyone. How much people succeed depends on just how much they dedicate their time and come up with ideas for the field. Passion for the field is key. I like the industry because both men and women are equally capable of being great in the field. Veterans Day is observed annually on November 11th, honoring those who have served honorably in the armed forces of United States. The day was chosen because it marks the anniversary of the end of World War I. The observance was originally known as Armistice Day, because major hostilities were formally ended at the 11th hour of the 11th day of the 11th month of 1918.

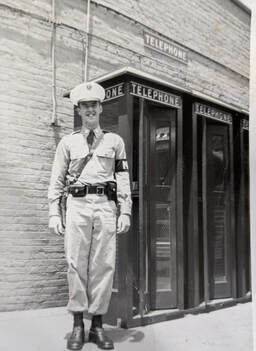

Again, this year, MDNA is privileged to celebrate the many veterans who have served our country. They deserve our highest praise. In recent weeks, it has been our pleasure to pay tribute to some of these heroes who have ties to the MDNA. Here is a recap of that recognition. Captain Bill Newton was an Army Air Corps air gunner during World War II. He also was a Scripps-Howard News Service war correspondent who covered the Japanese surrender on the deck of the battleship USS Missouri, where he later joked with friends that he’d "left a ring in (Gen. Douglas) MacArthur’s tub." During his career as a Scripps-Howard staff writer, he also reported on village life in Spain under the Franco regime and traveled with soldiers of Chiang Kai-shek's nationalist army during the Communist revolution in China. Newton was among 14 American news correspondents who died in the line of duty in a plane crash near Bombay, India, on July 12, 1949. He is the maternal grandfather of John Paff, owner and founder of MDNA Premier Vendor Fort Wayne Marketing. Larry Lachant served in the Army from 1955-1957 as a corporal in the 7th Army’s 4th Ordnance Battalion, Quartermaster Corps. He was stationed not far from UiJongBu, in present-day South Korea. He would tell his son Michael that, very much like the Cpl. Klinger character in the iconic TV show, “M*A*S*H”, he would get into trouble with his superiors for not filling out the proper paperwork before sending out supplies. He said he couldn't stand the thought of "his guys" freezing in trenches and foxholes waiting for gloves and boots and jackets, while the right paperwork was done, so he would just send it first and correct it later. After his time in the service, Larry founded MI-RO Machinery after working for MDNA member Federal Machinery. His son, Michael Lachant, CEA, grew up in the business and now runs MI-RO Machinery, in Woodbridge, NJ. Charles H. Thornton, III, is the father of Chip Thornton, CEA, and the grandfather of Chase Thornton, both of whom are with MDNA Member firm Presses for Industry, of Detroit. He served in the Army during the Korean War, from 1952-1954 as a military police officer (MP) stationed at Fort Knox, KY. Among his duties there was tracking down deserters — often in the wild and woolly Kentucky backwoods — as well as service members who were AWOL (absent without official leave). Charles H. Thornton, III, is now 90 years old and among a ever-smaller number of veterans of the Korean conflict. Army Private First-Class James Conway and Marine Sergeant Ryan Emmons are the father and stepson, respectively, of Mark Conway. Mark is with MDNA Member Tramar Industries, of Novi, MI. PFC Conway fought in Ardennes Forest Campaign — more commonly known as the Battle of the Bulge — and was wounded in action on December 13, 1944, earning his first Purple Heart. He was wounded again on December 21, 1944, earning a second Purple Heart. That injury took him out of action and he spent the remainder of the war recovering from his wounds. James Conway was honorably discharged in 1945 and spent the next 35 years working at Chrysler, retiring in the 1980s. He passed away in 2001. Sgt. Emmons served in the Marine Corps from 2000-2005 as a helicopter mechanic. He was assigned to the Presidential Helicopter Squadron (HMX-1) and traveled to South Korea with President George W. Bush. Today, Ryan works as a cybersecurity manager in Georgia. Through November 10th, we're proudly sharing the stories of U.S. Veterans. This week's spotlight is on U.S. Army Private First-Class James Conway and U.S. Marine Sergent Ryan Emmons, Father and Stepson, respectively of Mark Conway. Mark is with MDNA Member Tramar industries.

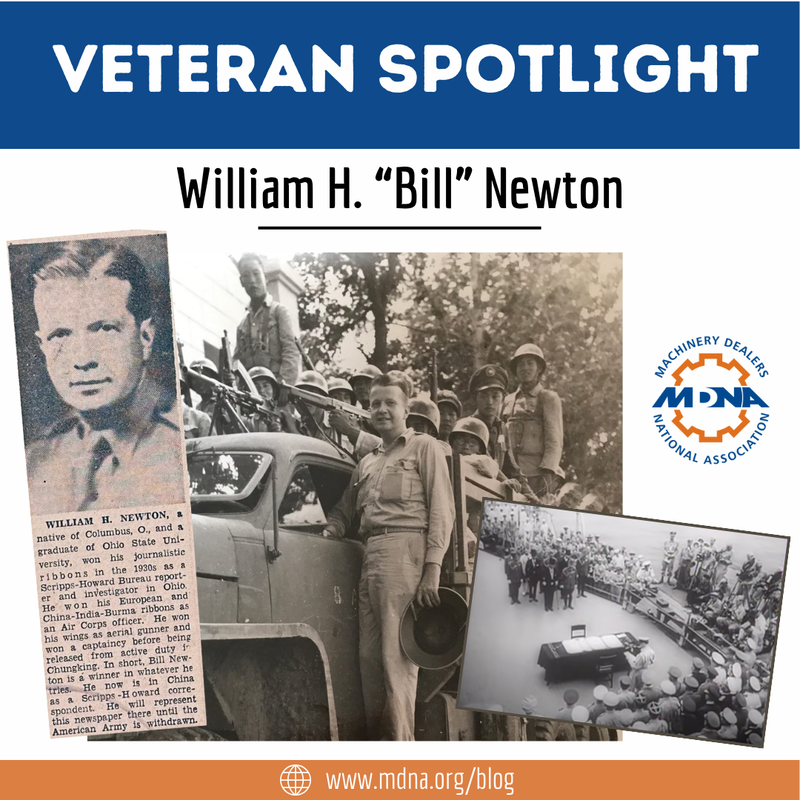

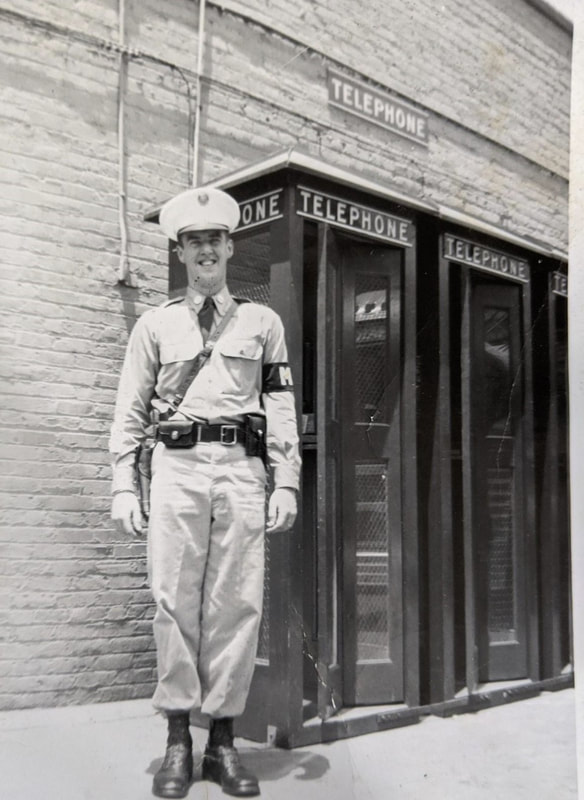

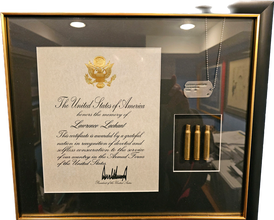

Mark’s father, Pvt First Class James Conway, known as “The Smiling Irishman” was a decorated World War II Combat Engineer. He enlisted in the army in 1940 and did his basic training at Fort Custard in Kalamazoo, MI. He was then stationed in Fort Worden WA from 1941-1944. He shipped off to France in July of 1944. In late December 1944, James fought in Ardennes Forest Campaign (the Battle of the Bulge), when German forces staged a massive drive to recapture lost areas in the Ardennes region of Belgium, France and Luxembourg, in what some say was Germany’s last stand. It was during this battle that James was wounded in action on December 13, 1944, earning his first purple heart. He was wounded again on December 21, 1944, earning as second purple heart. It was this injury that took him out of action, and he spent the remainder of the war recovering from his wounds. Private First-Class James Conway was honorably discharged in 1945 and spent the next 35 years working at Chrysler, retiring in the 1980’s. James passed away in 2001. _____________________________________________________________________________________ MDNA Veteran Spotlight: Sergent Ryan Emmons Mark Conway’s step son, Sergent Emmons served in the U.S. Marine Corps from 2000- 2005. His MOS (Military Occupational Specialty) was Helicopter Mechanic. He served in the Presidential Helicopter Squadron (HMX-1) and traveled to South Korea with President George W. Bush. Ryan Now works as a Cyber Security Manager in Georgia. _____________________________________________________________________________________ A grateful nation and the MDNA thank you for your service and are honored to celebrate you during our salute to all Veterans.  Through November 10th, we're proudly sharing the stories of U.S. Veterans. This week's spotlight is on Charles H. Thornton, III. He served in the U.S. Army during the Korean conflict, from 1952-1954. Charles was a MP (Military Police Officer) and was stationed at Fort Knox, KY. During his service he hunted down deserters and service members who had gone AWOL (absent without official leave). Charles H. Thornton, III is the father of Chip Thornton, CEA and grandfather of Chase Thornton, both of MDNA Member firm, PRESSES FOR INDUSTRY. Chip recounts hearing his dad talk about his time as an MP. “One story that he told us, always stood out to me. He and a partner would have to go up in the hills and back woods of Kentucky. He would always find himself stumbling on a Moonshine Still (guys making illegal Moonshine was very prevalent in those times). He said many times he would be looking down the barrel of a shotgun. He would say “I am only looking for so and so”, and the Moonshiners would always say go look at his Mama’s house. Sure enough that’s where they would find them. He also would hear the Moonshiner’s running their souped-up cars built for running the mountains at night with huge motors and stripped out so they could put all the crates of moonshine in the cars. And, when sitting in his vehicle at night during a stakeout they would always here the cars racing up and down the mountain and occasionally you could hear one drive off the cliff and explode or crash.” God bless Charles H. Thornton, III (still with us today at 90 years old), and thank you for your service. Are you or your loved one a U.S. Veteran? We want to celebrate your story too. Please send your story and photos to [email protected]. And thank you for your service! All through October, we're proudly sharing the stories of U.S. Veterans. This week's spotlight is on Larry Lachant. He served in the Army from 1955-1957, after the "police action" was technically over but guys were still being killed every day.

Larry Lachant was a Corporal in the 7th Army, 4th Ordinance Battalion, Quartermaster Corps. He was stationed not far from UiJongBu. He would tell his son Michael how volatile the weather changes were, one day it was in the 90's, the next it was below freezing. And very much like the Klinger character from the M.A.S.H TV show, he would get into trouble with his superiors for not filling out the proper paperwork before sending out supplies. He couldn't stand the thought of "his guys" freezing in trenches and foxholes waiting for gloves and boots and jackets while the right paperwork was done, so he would just send it and make it up later. After his service to the country, Larry founded MI-RO Machinery after working for MDNA Member Federal Machinery. Son, Michael Lachant grew up in the business and now runs MIRO Machinery. Are you or your loved one a U.S. Veteran? We want to celebrate your story too. Please send your story and photos to [email protected]. And thank you for your service! |

Categories |

|

Contact us: Phone:703.836.9300 | [email protected] | sitemap

Copyright MDNA-Machinery Dealers National Association. All Rights Reserved. 5568 General Washington Drive, Suite A213D, Alexandria VA 22312 |

RSS Feed

RSS Feed